SÄKERT MILJÖVÄNLIGT ALTERNATIV

Aquacode™ hjälper industrin, lantbruket och offentliga inrättningar att öka produktiviteten samt livskvaliteten för människor och djur genom att erbjuda maskiner som tillverkar desinfektionsvätska mot bakterier, virus, sporer och mögel till låg kostnad och utan användande av kemikalier.

Om elektrolysmaskiner (ECA)

ECA fungerar på samma sätt som det mänskliga immunsystemet.

När kroppen attackeras från invaderande bakterier och virus svarar immunsystemet omedelbart genom att skicka neutrofiler (vita blodkroppar) till invasionen.

Neutrofiler är ett av kroppens huvudsakliga försvar mot bakterier och producerar, när de aktiverats, stora mängder av en blandad oxidantlösning som är effektiv för att eliminera invaderande mikrober och patogener.

Denna svaga syra, som förekommer naturligt i människokroppen, kallas hypoklorsyra (HOCI) och är ett potent desinfektionsmedel. Det är ej giftigt för människor och är mycket effektivt som ett antimikrobiellt medel med snabb verkan. Hypoklorsyra är allmänt erkänd som en av de mest effektiva kända biociderna.

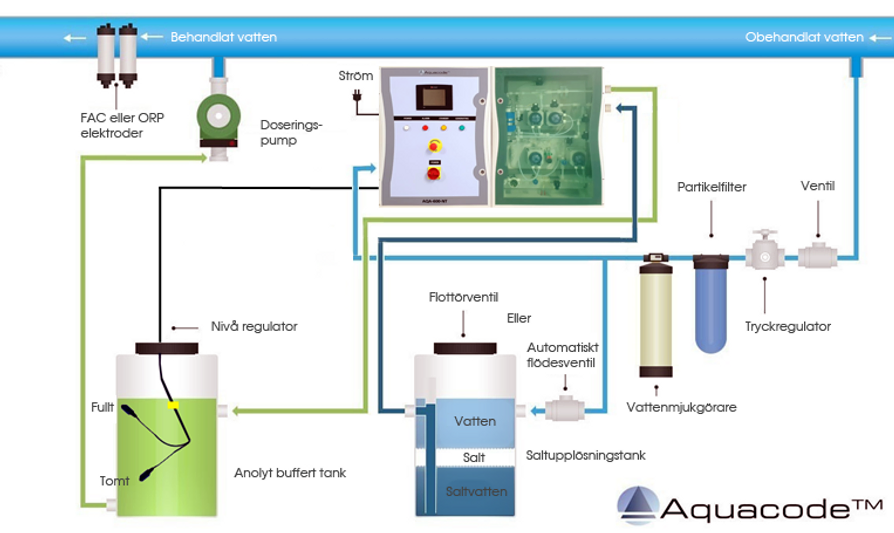

I detalj består systemet av en elektrolyscell innehållande två elektroder, en katod och en anod, åtskilda av ett membran.

I cellen injiceras en vattenlösning bestående av filtrerat och mjukt vatten och beroende på applicering, natriumklorid (NaCl, salt). Med användning av elektricitet med fördefinierade och kontrollerade ström- och spänningsvärden producerar cellen en elektriskt aktiverad vätska:

Anolyt, med hög desinfektionseffekt som kan användas i olika applikationer.

Desinfektionsvätska utan alkohol

Aqua4power™ – producerat från Aquacode™ maskiner är en vattenbaserad produkt som till skillnad mot alkohol och klorhexidin inte är giftig för kroppen. Den aktiva substansen hypoklorsyra eliminerar virus upp till 99,9% på 30 sekunder. Dessutom lika effektivt som handsprit och alcogel men är betydligt skonsammare mot huden.

Hypoklorsyra

HOCl är ett naturligt förekommande ämne som produceras i våra vita blodkroppar för att bekämpa bakterier och inflammationer efter en infektion. HOCl ger en unik kraft att utrota farliga organismer utan att skada våra celler. HOCl är ett av de enda medlen som kan läka våra sår samtidigt som de är dödliga för nästan alla kända farliga bakterier och virus som hotar vår hälsa.

PRODUKTER

VI HAR FLER MODELLER FÖR JUST DIN APPLIKATION

OM AQUACODE™

Aquacode™ – för de största industriområdet ner till minsta repa eller bränna på kroppen. Och allt däremellan.

Aquacode AB är den direkta utvecklingen från Aircode™ och de framsteg som vi har haft med våra långvariga kundrelationer. Vi har från några av våra kunder fått frågan om vi inte har en lösning för deras vattenproblem.

Frågorna har alltid varit: Kan man inte göra något lika användarvänligt som Aircode™. Vi har letat och försöka utveckla detta under några år och vi har haft ögonen på några alternativa lösningar men inte hittat något som var ”Aircode™ för vatten”.

För att vi skulle bli intresserade av en vattenlösning behövde vi en produkt som var ny, miljövänlig, användarvänlig och ekonomiskt lönsam för våra kunder. Vi ville inte ta itu med något som inte var ”naturens eget sätt”. Vi ville inte vara knutna till något kemiskt, med hög klimatpåverkan eller dyr vattenrening.

Så, här är det. Det är med stor stolthet och förväntningar som vi presenterar Aquacode™ till våra befintliga och nya kunder. Vi känner att vi har en bra produkt som inte bara kommer kommer att revolutionera våra kunders sätt att behandla vatten, sänka sina driftskostnader och ökar nettovinsten. Men också, att bli mer miljövänliga med en sensationell avkastningstakt.

Varför använda farliga kemikalier när det finns säkrare miljövänliga alternativ = Aquacode™!

Likheterna med sin syster produkt Aircode™ är slående. Att kunna arbeta med en produkt som har ett så brett användningsområde är otroligt. Att vi nu kan arbeta samtidigt med två produkter som så direkt har påverkan på två av de mest uppskattade inslagen vi har på jorden, vatten och luft är inget annat än fantastiskt. Aquacode™ kan gynna dig, från den största industrianvändningen ner till minsta sår eller utslag på kroppen. Och allt däremellan.

Oavsett om du är i behov av en av våra Aquacode™ enheter som skräddarsys efter dina behov i industri, publika byggnader, sjukhus eller avloppsverk eller om dina behov kan fyllas med vår Aqua4Power™ vätska för desinfektion som säljs i 5 liters dunkar önskar vi er varmt välkomna till morgondagens vattenrening

APPLIKATIONER

1) mjölkproduktion och mejeriindustrin

2) kött, fisk och kycklingindustrin

3) rengöring på plats (CIP) för livsmedels och dryckesindustrin

4) jordbruk, grönsaks och blomsternäringen

5) lantbruk med boskap, häst eller kycklinguppfödning

6) dricksvattendesinfektion och avloppsvattenrening

7) behandling av barlastvatten på fartyg

8) vattenbruk

9) hälso-och sjukvården

10) olje-och gasindustrin

11) vattenrening för kyltorn och kylsystem

12) simbassänger, desinficering av vatte

13) Veterinärvård

Aquacode™ har fokuserat på dessa marknader, eftersom vi vet att vi har konkurrensfördelar för varje av dessa marknader, är en ledande strategisk industri partner, eller så kan vi skapa ett attraktivt mervärde för våra kunder.

Bryggeri- och dryckesindustrin

Aquacode™ desinfektionsmedelsaggregat kan användas för ett antal olika applikationer som att desinficera processvattnet, tunnelpastörisörer, flasktvätt och rengöring av transportband och transportsystem. Användningen av ett Aquacode

aggregat resulterar i betydande besparingar eftersom det tillåter processer att köras vid lägre temperaturer och att vattnet kan återvinnas.

Kyltorn och dammar

Anolyt, tillverkad på plats med våra aggregat, håller effektivt kontroll på legionella och andra bakterier för att upprätthålla en säker och hälsosam miljö. Det kraftfulla desinficeringsmedlet förstör också biofilmen och är inte mer korrosiv än vanligt kranvatten.

Avloppsvattenrening

Genom att tillföra Anolyt till avloppsvatten, kan man minska den bakteriella belastningen utan att förorena miljön.

Livsmedels och mejeriindustrin

Då Anolyt är giftfritt är det godkänt för användning i livsmedelsindustrin för desinfektion för ett stort antal områden, inklusive beredning, rörsystem, transportsystem och förpackningslinjer.

Kött och charkuteri industrin

Bakteriell kontaminering av kött är ett ständigt och aktuellt problem. Aquacode™ kan med hjälp av sin kraftfulla Anolyt lösning sättas in där det är behov av ytrengöring och desinfektion. T.ex beredningsmaskiner, packlådor och transportsystem, men utan de problem som är förknippade med traditionella klorbaserade kemikalier.

Tvätt av frukt och grönsaker

Anolyt är ett mycket effektivt desinfektionsmedel för tvätt av frukt och grönsaker, både hela och skurna. Den ökar hållbarheten och ger konsumenterna en säkrare produkt.

Trädgårdsodling

Dimning eller sprayning av växthus med Anolyt ger en effektiv kontroll av bakterier och alger. Desinfektion av bevattningsvattnet ger bättre plantor och större tillväxt. Bättre motstånd mot ogräs, mögelsvampar, olika parasiter och sjukdomar. Bättre produktkvalitet på skörden utan ytterligare användning av gödningsmedel.

Dricksvatten

Anolyt är godkänt för användning som desinfektionsmedel för dricksvatten och ger ett vatten som är säkert för konsumtion, utan den obehagliga lukt och smak som man känner i samband med konventionell klordesinficerad vattenrening.

Simbassänger

Anolyt tillverkad på plats kan säkerställa en trygg bassängmiljö utan obehaglig lukt eller svidande ögon, effekter man känner av vid traditionella klorbaserade vattenbehandlingar. Det är också säkrare för personalen, eftersom de inte behöver hantera potentiellt farliga kemikalier.

Hotell och offentliga lokaler

Legionella är ett stort hälsoproblem i lokaler med stora vattensystem där t.ex duschar inte används ofta, som hotellrum under lågsäsong. I de oanvända områdena kan legionella och andra hälsofarliga bakterier bildas och växa till i vattensystemet. Genom att koppla ett Aquacode™ aggregat till sitt vattensystem kan man förhindra legionella ,utan kostsamma högtemperaturspolningar av ledningsnätet.

Fisk och skaldjur

Anolyt har visat sig vara mycket effektiv i att eliminera bakterier som kolera och E-coli Användande av Anolyt vid hantering av fisk och skaldjur, ger konsumenterna en säkrare produkt.

Sjukvårdsinrättningar

Anolyt är ofarligt för hälsan och är inte korrosivt, vilket gör den idealiskt för sterilisering av medicinsk utrustning ,för att förhindra bakteriella infektioner. Kall sterilisering av medicinska instrument, rengöring av ytor, inklusive väggar, möbler och golv. Kan användas vid desinfektion av sjukhustvätt. Desinficering av luften genom dimning med Anolyt eliminerar / minskar användningen av kemikalier.

Lantbruk och boskapsuppfödning

Anolyt används för allmän desinfektion och städning av ytor och utrustning. Genom att dimma Anolyt får man en bra kontroll på aeroba och anaeroba bakterier. Med Anolyt som dricksvattentillsats främjas foderassimilation och allmän hälsa (minskar dödlighet). Garanterar eliminering av hudparasitsjukdomar.

Jordbruk

Användningen av Anolyt i jordbruket kan resultera i en ökad avkastning och en förbättrad djurhållning genom att eliminera bakterier i djurens dricksvatten och foder.

Veterinärmedicin

Ökar vitalitet och motståndskraft, förbättrar fertiliteten. Behandling av juverinflammation, diarré och andra infektioner utan kemiska preparat. Behandling av foder med Anolyt ökar fodervärdet. Minskar djurens anspänning. Ökar djurens tillväxt och avkastning. Ger en effektivt kontroll och är ett botemedel för de allvarligaste sjukdomarna.

Olje-och gasindustrin

Anolyt- och Katolytlösningar används för att stimulera och förbättra olje- och gasproduktion och för att förbättra prestanda på borrvätskor. Anolyt är ett mycket effektivt alternativ till baktericider, som inte är biologiskt nedbrytbara eller är bioackumulativa. Anolyt är en selektiv baktericid som eliminerar bakterier, som påskyndar korrosion samtidigt som de är ofarliga för människan.

Marina industrin

Aquacode™ aggregat som producerar Anolyt, är lämpliga för sterilisering av dricks- och ballastvatten ombord på fartyg. Anolyt kan också blandas i vatten som används till is för fiskerinäringen för att öka produkternas hållbarhet och ge en säkrare produkt.

HUR FUNGERAR DET

TEKNIK

Banbrytande ny teknologi inom sterilisering, desinfektion och vattenrening

ELEKTROLYS JONISERAD- ELLER IONIZED VATTENLÖSNING

Aquacode™ elektrolys Water (EW, EOW eller EO, även känd som elektrolys joniserad vattenlösning eller ionized vattenlösning) -teknik. En process där vanligt vatten och en utspädd saltlösning passerar genom en speciellt utformad elektrolytisk cell, för att ändra salt/ vattenlösningens funktionella egenskaper utan att tillföra reagenser.

Aquacode™ lösningarna (anolyt och katolyt) har visat förmåga att:

- Förstöra mikroorganismer som gråmögelsvamp, salmonella, e-coli, listeria och mjältbrandsporer,

- Rena vatten och avloppsvatten

- Rengöra och avfetta

Aquacode™ skräddarsyr, marknadsför, monterar och säljer utrustning som kan producera två olika typer av vätskor:

1. Anolyt lösningar som är starkt oxiderande lösningar med pH värden mellan 2,5 ± 8,5 och en Oxidation förmåga (ORP) av 600 till 1200 mV. Anolyt kan potentiellt användas som ett bredspektrum bakteriedödande medel för att döda alla typer av mikroorganismer, inklusive virus, svampar och bakterier.

2. Katolytlösningar är antioxiderande, milda alkaliska lösningar med pH värden från 10,5 till 12,0 och ORP av -600 till -900 mV. Katolytlösningar kan potentiellt användas som avfettningsmedel, rengörings- och tvättmedel.

Baserat på omfattande forskning, som visar att våra produkter, både anolyt och katolyt:

- Är miljövänliga

- Inte är giftiga för både människor och djur

- Inte kräver särskild hantering

- Är kraftfulla biocider

- Kan säkert avledas till avloppsvattensystem

- Är snabbverkande

- Kan användas i alla typer av desinfektion och rengöringsapplikationer

- Bleker inte ytor och material vid rekommenderade koncentrationer

- Kan appliceras i flytande form, som is eller som aerosol (dimma)

- Inte ger allergiska reaktioner

- Ger inga biprodukter som är giftiga, skadar miljön eller lämnar syntetiska kemiska rester

- Kan tillverkas på plats, vilket eliminerar hantering och lagring av kemikalier

- Kan tillverkas på plats från dricksvatten och koksalt i erforderliga kvantiteter och koncentrationer av aktiva substanser, pH och salthalt (Mineralisering)

Anolyt innehåller bland annat Hypoklorsyra som är en mycket potent baktericid. Bakterier som Escherichia coli (E-koli) förlorar sin skadliga verkan på mindre än 100 ms när de utsätts för hypoklorsyra. Escherichia coli (E-koli) är en viktig förorsakare av livsmedelsoch vattenburna infektioner hos människor.

Förutom att döda bakterier är Anolyt effektivt i att bryta ner biofilm, som skyddar bakterierna från inverkan av hypoklorsyran.

Som ett desinfektionsmedel för hårda ytor, har Anolyt sedan mer än ett decennium visat, att även vid daglig användning utvecklar mikroorganismer ingen immunitet mot Anolyt. Detta medför att det är möjligt att använda Aquacode™ utrustningar på ett stort antal områden där man fokuserar på personlig säkerhet och människor och djurs hälsa.

MER OM TEKNIKEN

Hjärtat i Aquacode’s teknik är vår cylindriska cell som är den enda produkten på marknaden med ett dubbelkyldelektrodsystem: anod- och katodelektrodkyld.

Till skillnad från andra elektrolytiska celler separerar ett membran Anolyt och Katolytlösningarna som genereras vid respektive anod och katodkamrarna i cellen. Detta förhindrar att de två strömmarna blandas och bildar en enkel natriumhypokloritlösning vilket är fallet med många andra kommersiellt tillgängliga elektrolytiska celler. Våra celler är modulära och kan plockas isär vid behov.

Tekniken innehåller komponenter uppbyggt på ett unikt sätt. Till skillnad från andra cylindriska koaxialceller, som idag är de vanligaste så har vår cell optimerats, utformats och utvecklats med en speciell anodgeometri som har möjliggjort integrering av ett dubbelelektrod (anod-katod) kylsystem.

Liknande elektrolysapparater har varit kända tidigare, men det var först i slutet av 70-talet som EW teknik utvecklades av det Ryska institutet för medicinsk och vetenskaplig forskning. Tidigare modeller av EW produkter såldes i hela forna Sovjetunionen, i allmänhet för att desinficera vatten och för sterilisering på sjukhus.

Den uppfinning Aquacode™ använder gör det möjligt att avsevärt utvidga dess kommersiella tillämpningar och ger i detta hänseende Aquacode™ en obestridliga fördel över befintliga konkurrenter. Vår cell är en membrancell som är jongenomsläpplig och separerar vätska men också tillåter jonbyte på grund av porositetsstrukturer.

Aquacode™ celler tillverkas med varierande produktionsvolymer.

Allt från 5L /h till 1200L /h anolyt per cell.

Kombination av celler gör det möjligt att tillverka Aquacode™ enheter med högre kapacitet.

Anolyten kan antingen doseras direkt i ditt system,

eller alternativt till en ackumulatortank om behovet av

dosering är varierande. Med hjälp av en sensorstyrd doseringspump anpassas doseringen till den biologisk belastningen i ditt system.

Krav på våra system: tillgång till salt, vatten och el.

Generatorerna kan styras av PLC med en

enkel att använda HMI (Human Machine interface) som gör det möjligt för slutanvändaren att exakt kontrollera Anolytens pH-värde och rätt dosering för en viss tillämpning.

Genomsnittlig kostnad för att tillverka 1000 liter av anolyt i ett europeiskt och nordamerikanskt land är ca 3 EUR.

Detta gör vätskan till ett mycket kostnadseffektivt alternativ till många använda kemikalier idag.